Who Is Remette?

Pause for a moment and try a little thought experiment: What would you consider a “high-performance material”? Such a richly associative term tends to make one think about industries such as aeronautics, computing, manufacturing, national security, and healthcare. Perhaps you imagine substances like titanium, Kevlar, cobalt-chromium-molybdenum alloys, and high-grade elastomers (e.g., thermoplastic polyolefin elastomers, polycarbons). And while all of these materials would certainly qualify, it’s worth remembering that “high-performance” describes something that performs robustly within certain parameters — not necessarily the newest or most flashy substance.

Such is the case with Micarta, a type of material that deserves the “high-quality” label even if it’s far from the newest substance on the proverbial block. In this article, we will explain what Micarta is, its advantages and limitations, and why it has become a popular component in many different kinds of knives.

Micarta: High Performance from Humble Components

As we alluded to in the prior paragraph, Micarta isn’t a recent creation. A trademarked property of the company Norplex-Micarta, it originated in the early 20th century as an invention of the Westinghouse Electric & Manufacturing Company. Norplex acquired it in 2003, adding Micarta to its stable of epoxy, melamine, silicone, and phenolic resin offerings. Today, Norplex makes Micarta in more than a hundred formulations and various raw forms (e.g., tubes, rods, sheets).

So what is Micarta exactly? Well, to get technical, it’s a composite resin comprised of a thermosetting plastic and a strengthening matrix material. Micarta traces its origins to Bakelite, a phenol formaldehyde resin created in 1909 that was originally intended as a shellac substitute. However, the substance proved quite hard and nonconductive, as well as easy to form into various shapes, although it was also somewhat brittle. Bakelite became an early 20th century staple in electrical insulation, radios, cars, aeronautics, military equipment, and televisions. When Westinghouse combined Bakelite with other strengthening materials, a much stronger material — Micarta — was born.

Micarta originally found applications in many of the same areas as Bakelite. Propellors, electrical insulation, auto components, hard hats, and furniture have all been crafted from Micarta, and early circuit boards used it extensively as a substrate. At some point, knifemakers noticed that this older industrial substance was quite strong, resisted wear, and could take on many different kinds of textures and colors. It was only a matter of time before it made a major impact on the market.

Unfortunately, Micarta has become something of a victim of its own success and has suffered from (to use a technical term) genericide. Just as Coke, Jacuzzi, Xerox, Frisbee, Band-Aid, Hula-Hoop, and Super Glue have come to represent product categories rather than the trademarked goods they actually are, Micarta has come to represent *any* thermosetting plastic composite. It’s not that generic, though. True Micarta contains phenolic resin, as well as paper and cotton as matrix material. Other related materials exist, but they won’t offer the same benefits in the same way as the branded substance.

The Advantages and Limitations of Micarta

Though Micarta’s century-plus of usefulness testifies to its enduring appeal, no material comes without downsides. One of the most impactful is that Micarta isn’t necessarily the cheapest handle material that you purchase. Other composite laminates often have a less expensive price point, and when one wants a truly budget blade option, Micarta may push it into more expensive territory.

Another limitation with Micarta is that some have complained about its tendency to absorb liquids. Note that Micarta is nowhere near as susceptible to moisture as natural materials such as leather, cloth, bone, wood, or nacre. But just because it exhibits some degree of resistance doesn’t mean that Micarta is moisture proof. It’s not. If you’re using a knife with a Micarta handle to skin game or should you happen to get oil on it, be aware that you may experience discoloration. Additionally, long use can also lead to unsightly blemishing of the finish.

Finally, like other similarly tough composites, Micarta has a particular vulnerability, namely that it’s somewhat brittle. Hard, sharp, or sudden impacts can lead to chipping or cracking of a Micarta handle. Fortunately, such stresses are generally rare provided that one exercises appropriate care. Batoning (i.e., the process of splitting a log by hammering a knife into a crack with another object) runs the risk of real damage. When selecting a survival-type knife, consider selecting a blade that has a different handle material should you intend to put it to hard use.

Of course, should you simply employ a folding pocket knife in a more standard manner, the toughness of a Micarta handle will serve as a definite advantage. Whether it rides in a pocket, a backpack, a vehicle (or even knocking about around the floorboards of that self-same vehicle), such a knife will stand up to friction, minor impacts, and dirt and grime. There’s a reason why so many everyday carry knives feature Micarta handles: The material’s inherent toughness helps guarantee a long life for any tool.

Another reason why knifemakers love Micarta is the ease with which they can color, texture, and shape it. Resin-impregnated paper doesn’t sound like a particularly aesthetically pleasing combination, but make no mistake about it. Micarta can take on a wide variety of looks, taking on the appearance of everything from wood to neon-bright primaries to dark synthetic “tactical” looks. You might be shocked to learn that a particularly fine-looking handle is Micarta rather than a higher-end type of material.

Finally, Micarta feels really nice to hold, particularly when properly textured. True, raw Micarta can prove a bit slippery, but that’s a form of the substance that you won’t find in the finished-knife market. Shaped and textured Micarta is the norm, and unlike materials such as aluminum and other metals, it warms up nicely in the hand and is easy to grip. When it comes to Micarta, comfort is king.

Why Is Micarta So Popular with Knife Makers?

Hopefully, it’s evident why Micarta has made such a splash with knife maker even though different kinds of similar materials exist, such as G-10, Ultem, reinforced nylon, and carbon fiber. Micarta became a popular choice because, for one thing, it’s a tried-and-true material, one whose strengths are well known. It combines hardiness with the ability to cast, color, and shape it in any number of ways. And while it isn’t the least expensive option available, it’s usually quite budget friendly.

TacKnives has numerous offerings that feature Micarta handles. Check them out here.

-

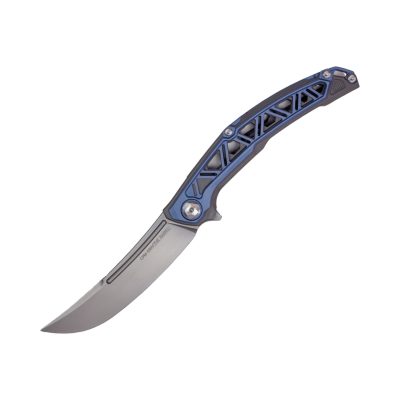

Rated 5.00 out of 5$129.95 – $169.96Price range: $129.95 through $169.96Select options This product has multiple variants. The options may be chosen on the product page

-

Rated 5.00 out of 5$59.95Select options This product has multiple variants. The options may be chosen on the product page

-

Rated 4.67 out of 5$65.95Select options This product has multiple variants. The options may be chosen on the product page