Who Is Remette?

People do not always think correctly or precisely. That’s likely no surprise to you if you’ve ever sat through a family dinner with Uncle Earl or watched a televised debate during an election season or tried to hold your tongue at a family dinner held immediately after a political debate where Uncle Earl opines at length over his pet issue du jour. The mistakes, errors, and distortions that get made, introduced, or indulged in are called cognitive biases, and there are a whole bevy of them. Familiarity and social pressure, evidence availability and preference for one’s particular group, tending to trust things that confirm existing beliefs and clinging to past costs — these and many similar phenomena distort our perceptions.

This is even true when it comes to knives of all kinds, including OTFs, folding knives, and fixed blades. Believe it or not, knives are actually quite complex, and when faced with complex subjects, individuals tend to simplify them, swapping out nuance for uniformity. You see this when people try to evaluate difficult ethical problems, indulge in stereotypes, or (to return to the election example) evaluate a candidate based on party affiliation rather than policy positions and personal character. Experts call this attribute substitution. When it comes to knives, you see it when potential buyers discount things like the type of steel used in a blade. “All steel is basically the same,” they declare.

Such an assertion couldn’t be further from the truth, particularly when it comes to stainless steel and carbon steel, two metals commonly found in knives. In this article, we will compare stainless steel and carbon steel, explain the advantages and disadvantages or both, and talk about when you should select one over the other.

Starting With the Basics: What Differentiates Steel from Other Ferrous Metals?

Instead of immediately tackling the differing characteristics of carbon steel and stainless steel, let’s begin at the beginning, which is always a good place to start. When classifying metals, scientists tend to approach them in one of two ways. Academic types prefer to delineate metals according to their atomic structure, and while this allows for some very precise classifications, it can fall a little short in the practicality department. The second means of classification involves sorting metals depending on their iron content. Those who use this system broadly categorize all metals as either ferrous or non-ferrous.

This easy-to-understand system puts all metals that lack any iron content into the non-ferrous category. While they share some common characteristics such as malleability, corrosion resistance, and a lack of magnetism, these metals are quite diverse, including everything from aluminum, copper, and zinc to silver, gold, and platinum. For their part, ferrous metals contain iron and exhibit magnetism, durability, and corrosiveness. They’re also typically silver in color, conduct electricity, and can be recycled. And the most common ferrous metal is iron, the father of both stainless steel and carbon steel.

Despite iron’s status as an element and the fourth most abundant one in the earth’s crust, even it defies easy classification. Practically speaking, there isn’t just one kind of iron whose characteristics remain static across all examples. Humans have used varying types of iron, which exhibit subtle and not-so-subtle variations. Examples include pig iron (raw iron that has been smelted); wrought iron (highly refined iron that contains small amounts of silicate); and cast iron (liquified pig iron combined with limestone and coke, a fuel derived from oil and/or coal). While these materials are called “iron,” you can see that most of them contain substances other than atomic element number 26, and when one mixes in those other substances, one technically has an alloy — and the most common ferrous alloy is steel.

Steel alloy includes two ingredients: iron and carbon. Combined, the resulting metal enjoys all the typical characteristics of iron, but also exhibits increased strength and resistance to breaking. This is why steel is one of the most manufactured metals on the planet. However, this simple recipe is only the beginning when it comes to steel.

Attributes of Steel

Carbon steel and stainless steel behave very differently in everyday situations. But rather than speak in generalities, let’s review some common technical terms used to describe metals. These definitions will provide us with a clearer picture of the distinctives of carbon and stainless steel.

Hardness

The word “hardness” may seem self-explanatory, but it has a somewhat specialized meaning when dealing with metals. Experts define hardness as the ability of a metal to avoid warping when subjected to applied force that could leave an indentation. The harder the metal, the greater its resistance.

There are two commonly accepted hardness scales, namely the Mohs scale and the Rockwell test. The former functions by scratching a substance with a number of previously ranked, standard materials, starting with the softest and moving by degrees to harder ones. Lower numbers correspond with softer minerals and the higher with harder. The softest number to leave a lasting scratch on the tested substance will grant it its Mohs ranking. The Mohs scale is primarily used by jewelers, but steel has been ranked on it and resides somewhere between 4 and 4.5.

The more common measuring system for knife makers is the Rockwell test. While this test also uses a scratch imparted by different machines featuring varying striking implements that use discrete amounts of force to determine hardness, the actual ranking system is far more complicated, employing a bevy of alphanumeric codes to denote hardness. All that potential purchasers need to know is that the vast majority of steels lie on the HRC section of the scale with higher numbers indicating greater hardness.

Toughness

Toughness represents something very different from hardness. In fact, they generally have an inverse relationship to one another. Toughness represents a metal’s ability to withstand force without breaking. The standard toughness test is the Charpy V-notch test. By striking a uniform sample of a material with a pendulum-dropped hammer that applies increasing amounts of force until the sample breaks. Harder metals tend to be more brittle and less tough.

Edge Retention

In order to put an edge on a piece of metal, you need to remove some of it at a certain angle so that it can cut. As you use it, that angle will gradually wear away, impacting its ability to slice. The length of time until a blade begins to dull, until small bits of metal start to wear away, is commonly called edge retention. Edge retention has a positive relationship to hardness and an opposite relationship with ease of sharpening; a really hard metal will stay sharp for a long time, but an owner may struggle to restore its edge if he doesn’t have specialized tools.

Corrosion Resistance

When water and oxygen meet, they become public enemy number one of ferrous metals. In fact, a defining characteristic of iron and related metals is that this combination makes them oxidize (i.e., rust). Still, not all ferrous substances will rust at the same rate, and a few can withstand damp conditions for extended periods. We refer to this quality as a metal’s corrosion resistance.

The Characteristics of Carbon Steel and Stainless Steel

Now that we have a common vocabulary with which to describe different steels, let’s discuss the tangible differences between different steel types. Remember how we explained that the two basic ingredients of steel were iron and carbon? Well, this simple combination is technically called mild steel or low-carbon steel. With a carbon content of anywhere from 0.05 to 0.25 percent, it’s cheap to make, easy to machine, and simpler to weld. But mild steel is nearly impossible to harden, which somewhat limits its applications.

Enter both carbon steel and stainless steel, two different alloys that differentiate themselves from mild steel in striking ways. Both metals are used in knives, though their unique characteristics make for very different kinds of blades. The reasons why make more sense once you understand their composition and characteristics.

Carbon Steel: A Basic Process Leading to Better Strength

Though many OTF and EDC knives you’ll encounter today contain stainless steel, carbon steel is actually incredibly common across many diverse industries. Part of the reason why owes to its inherent simplicity. Carbon steel is basically two ingredients, with iron comprising the vast majority of the material and carbon having a presence of up to 2.1 percent. You may find various other substances in carbon steel, such as vanadium, cobalt, titanium, and nickel. For carbon steel to remain carbon steel, though, it needs to have an *absence* of certain elements. It cannot contain more than 0.4 percent copper, 1.65 percent manganese, and 0.6 percent silicon and copper, respectively. At the end of the day, carbon steel needs to be mostly iron and carbon, but that carbon content needs to be significantly higher than that of mild steel.

Now what benefit exactly does that combination of iron and carbon grant to carbon steel? Hardness, hardness, and more hardness. Carbon steel is an incredibly hard metals, and with that hardness comes increased edge retention. This is why swordsmiths in Japan, the Middle East, and India employed various carbon-steel formulations to use in their weapons. When warriors went up against combatants whose swords contained some inferior formulation, they had a distinct advantage.

Where carbon steel suffers, though, is in ability to resist rusting. Even high humidity can cause this metal to begin to oxidize, and it will begin to rapidly degrade if not constantly cared for. It also can prove difficult to sharpen.

Stainless Steel: Durability Over Other Advantages

The longer you study metal types, the more you come to realize that stainless steel is a vast category encompassing many discrete metals. Still, we can isolate some commonalities. All stainless steels contain additional alloying components, the most prominent of which being chromium, which must comprise no less than 10.5 percent of the metal. Stainless steel also dials down the carbon content to no more than 1.2 percent. Sometimes, producers may also add nickel (up to 8 percent) and small amounts of molybdenum, both of which provide added corrosion resistance.

Unsurprisingly, when compared with carbon steel, stainless steel suffers a significant impact to hardness and edge retention. Expect most stainless-steel knives to dull more quickly due to their decreased hardness, but know that it will be far easier to sharpen. As the name itself proclaims, stainless steel also performs an admirable job of resisting oxidation and other forms of metal damage. Stainless-steel knives are far less brittle than those made out of carbon steel, standing less of a chance of cracking or shattering when twisted.

Use Cases: When Should You Prefer One Steel Over Another?

We’ve repeated time and again that there’s no such thing as one “best” steel. Just as knives are created with different use cases in mind, so steels get formulated to function in different contexts. That being said, we can offer some general about when one steel will function better than another.

Because carbon steel holds an edge for such a long time, it excels when you need a knife that can make fine cuts for an extended period. There’s a reason why chefs swear by carbon steel knives — and why they work so well in an environment where they can be constantly cleaned. The ever-present danger of rust means that carbon steel simply doesn’t work all that well with an EDC. A few knife makers will use carbon steel with their survival knives, but they always make sure to provide them with a protective coating. Know, though, that any damage to this coating puts your knife at serious risk.

For all the places where carbon steel lags, stainless steel steps up to the proverbial plate. Need to quickly prune something in your garden? Have some game you need to dress? Get caught out in the rain? Stainless steel can take it. This doesn’t mean that you won’t need to carefully clean and care for your knife later. No ferrous metal is entirely impervious to rust. However, it provides superior protection against moisture.

Here at TacKnives, we sell knives made out of many kinds of metal. Browse our selection here.

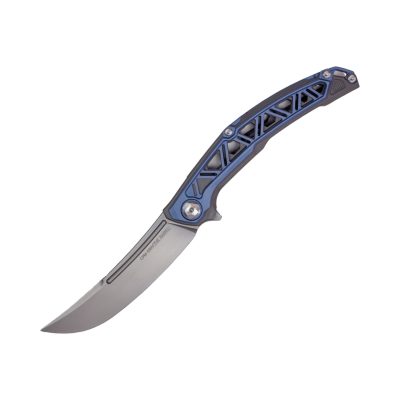

Browse Our Folding Pocket Knives

-

Rated 5.00 out of 5$129.95 – $169.96Price range: $129.95 through $169.96Select options This product has multiple variants. The options may be chosen on the product page

-

Rated 5.00 out of 5$59.95Select options This product has multiple variants. The options may be chosen on the product page

-

Rated 4.67 out of 5$65.95Select options This product has multiple variants. The options may be chosen on the product page